Choosing the right radiator for your vehicle is like finding the perfect partner for your engine—it can make all the difference. An aluminum radiator, particularly a 3-row variant, plays a crucial role in an automotive cooling system, efficiently managing heat and enhancing performance. With its lightweight nature and superior heat dissipation capabilities, aluminum is quickly becoming the material of choice in vehicle radiators. But how do you pick the right one for your car? From sizing and configuration to understanding core designs, our guide will walk you through everything you need to know to make an informed decision.

Aluminum Radiators in Automotive Cooling Systems

Transitioning to an aluminum radiator can significantly enhance your vehicle’s cooling system. Let’s delve into the benefits and impacts of aluminum radiators on automotive performance.

Aluminum Benefits in Vehicle Radiators

Aluminum radiators have become a popular choice in the automotive industry due to several key advantages. Firstly, aluminum is a lightweight material, which is beneficial for reducing the overall weight of a vehicle. This is crucial for performance vehicles, where every pound counts toward achieving better speed and fuel efficiency.

Additionally, aluminum’s thermal conductivity is superior, meaning it transfers heat more effectively than some traditional materials like copper or brass. This efficient heat dissipation ensures that the engine remains at an optimal temperature, preventing overheating and allowing for more consistent performance. Aluminum is also resistant to rust and corrosion, which contributes to a longer lifespan and less frequent need for replacements.

Lastly, aluminum radiators are known for their quick heating properties. This can be particularly advantageous in colder climates where warming up the engine more rapidly is desired. However, this efficiency comes with the trade-off of a higher initial cost, but many find the investment worthwhile due to the long-term savings on energy and maintenance.

Aluminum Radiator Impact on Engine Performance

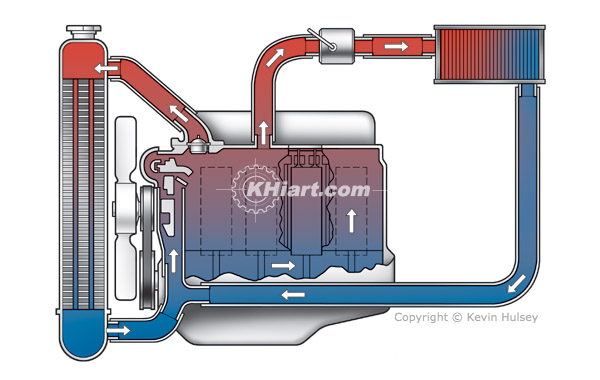

The impact of an aluminum radiator on engine performance is profound. By maintaining a steady engine temperature, aluminum radiators help optimize the engine’s operational efficiency. An engine that runs too hot can suffer from reduced performance and potential damage, while an engine that runs too cool may not operate efficiently.

With an aluminum radiator, the risk of overheating is greatly minimized, which helps in preserving the engine’s integrity and extending its life. The enhanced cooling capacity of aluminum radiators allows engines to perform at higher levels without the risk of thermal stress. This is particularly beneficial for high-performance or racing vehicles that operate under extreme conditions.

Moreover, the improved cooling efficiency can lead to better fuel economy. When the engine operates at its optimal temperature, it burns fuel more efficiently, which can result in cost savings over time. By integrating a 3 Rows Aluminum Radiator, the cooling system’s capacity is further increased, providing additional surface area for heat dissipation, which is critical for high-demand applications.

In summary, aluminum radiators not only bolster the cooling system’s performance but also enable the engine to deliver its best performance consistently. These benefits make aluminum radiators a top choice for anyone looking to enhance their vehicle’s cooling capabilities and overall performance.

Key Vehicle Radiator Selection Factors

When selecting a radiator for your vehicle, understanding your specific needs and the various factors that influence performance is essential. Here’s a breakdown of what to consider when choosing the perfect radiator.

Car Cooling Needs Assessment

The first step in selecting the right radiator is assessing your car’s cooling requirements. Every vehicle is unique, with different engine sizes, performance levels, and operating conditions. High-performance vehicles or those used in extreme environmental conditions may demand more robust cooling solutions than standard commuter cars.

To determine your car’s cooling needs, consider the engine’s horsepower, the climate in which the vehicle operates, and the typical driving conditions. For instance, vehicles in hotter climates or those frequently used for towing or racing will benefit from radiators with higher cooling capacities. Understanding these needs helps ensure your radiator can adequately manage the thermal demands of your engine.

Proper Sizing & Fitment Significance

Once you’ve assessed your cooling needs, the next crucial aspect is ensuring the radiator is properly sized and fitted for your vehicle. A radiator that doesn’t fit correctly can lead to inefficient cooling and even engine damage.

Start by consulting your vehicle’s specifications to determine the appropriate dimensions and compatibility. It’s also vital to consider the space available under the hood, as different vehicles have varying constraints. A well-fitted radiator not only ensures optimal cooling performance but also maintains the structural integrity of the vehicle’s engine bay.

Proper sizing also involves selecting the right number of rows. A 3-row aluminum radiator might be ideal for vehicles requiring enhanced cooling due to its increased surface area, which allows for better heat exchange and cooling efficiency.

Radiator Core Design & Efficiency Evaluation

The radiator core design plays a significant role in its efficiency. The core is the central part of the radiator where the coolant flows and heat exchange occurs. There are various core designs available, each offering different levels of performance.

Key core designs include tube-and-fin, plate-and-fin, and the more advanced serpentine fin designs. Tube-and-fin designs are traditional and cost-effective, while plate-and-fin designs offer improved heat dissipation due to increased surface area. Serpentine designs further enhance this by allowing more airflow and better cooling efficiency.

When evaluating core efficiency, consider the material of the core, the number of rows, and the overall design. Aluminum cores are preferred for their lightweight and excellent thermal conductivity. A 3-row core provides a balance of cooling efficiency and compact size, making it suitable for many performance applications.

In summary, selecting the right vehicle radiator involves a comprehensive assessment of your car’s cooling needs, ensuring proper sizing and fitment, and evaluating the core design for efficiency. By taking these factors into account, you can choose a radiator that not only meets your vehicle’s requirements but also enhances its overall performance.

Enhanced Cooling Aluminum Radiator Types

Understanding the different types of aluminum radiators is crucial for selecting the one that best suits your vehicle’s cooling needs. Let’s explore the various types and their specific advantages.

Single-Pass vs Dual-Pass Radiators

The design of a radiator significantly impacts its cooling efficiency, and one of the essential design aspects is whether it is a single-pass or dual-pass radiator.

In a single-pass radiator, the coolant flows from one side to the other in a single pass. This design is straightforward and effective for many standard vehicle applications, offering a balance of performance and cost. However, for vehicles that require enhanced cooling, such as high-performance or racing cars, a dual-pass radiator may be more suitable.

A dual-pass radiator routes the coolant through the system twice, effectively doubling the cooling opportunity. This results in up to 15% more efficiency in heat dissipation compared to its single-pass counterpart. The increased contact time between the coolant and the radiator’s surface area allows for superior heat transfer, making dual-pass radiators ideal for high-demand environments.

Crossflow vs Downflow Configurations

Another important design consideration is the configuration of the radiator—crossflow versus downflow. These terms refer to the direction in which the coolant moves through the radiator.

Crossflow radiators allow the coolant to flow horizontally, entering on one side and exiting on the opposite side. This configuration is often more efficient as it can provide a larger surface area for air to pass over, enhancing cooling performance. Crossflow designs are also suitable for modern cars with lower hood lines, as they can be more compact.

In contrast, downflow radiators have the coolant move vertically from the top to the bottom. While this traditional design is less common in performance applications, it can be beneficial in vehicles where vertical space is more plentiful, and simplicity is preferred.

The choice between crossflow and downflow will depend on your vehicle’s design and cooling requirements, but crossflow radiators often edge out in terms of efficiency and compact design.

Triple-Row Core Benefits

When it comes to maximizing cooling efficiency, the number of rows in a radiator’s core can make a significant difference. Triple-row cores are particularly beneficial in applications where enhanced cooling is necessary.

A triple-row core radiator features three sets of tubes through which the coolant flows, offering a substantial increase in surface area compared to single or double-row variants. This increased surface area means more heat can be dissipated, which is crucial for maintaining optimal engine temperatures under high-demand conditions.

Triple-row radiators are especially advantageous in performance vehicles, heavy-duty applications, or any situation where preventing engine overheating is a top priority. They represent a perfect blend of enhanced cooling capacity without excessively increasing the radiator’s size, making them a popular choice for those seeking efficiency without compromise.

In conclusion, understanding the various types of aluminum radiators and their configurations can help you choose the best option for your vehicle’s specific needs. Whether you’re looking for the simplicity of a single-pass design, the efficiency of dual-pass, the compactness of crossflow, or the enhanced capacity of a triple-row core, there’s a solution that fits perfectly with your cooling requirements.

ALLOYWORKS: Vehicle Accessories Brand Leader

When it comes to vehicle accessories, particularly aluminum radiators, ALLOYWORKS stands out as a leader in the industry. Known for their innovative designs and high-quality products, ALLOYWORKS has earned a reputation for excellence in automotive cooling solutions.

ALLOYWORKS Aluminum Radiator Options Overview

ALLOYWORKS offers a diverse range of aluminum radiators tailored to meet various automotive needs. Their product lineup includes options suitable for everything from everyday commuter vehicles to high-performance racing cars. Each radiator is crafted with precision, using top-grade aluminum that ensures durability and optimal heat dissipation.

One of the key features of ALLOYWORKS radiators is their availability in different configurations, including single-pass and dual-pass designs, as well as crossflow and downflow options. This variety allows customers to select a radiator that perfectly matches their vehicle’s cooling requirements and space constraints. Moreover, ALLOYWORKS offers triple-row core radiators, providing enhanced cooling capacity for applications that demand superior performance.

In addition to their standard offerings, ALLOYWORKS also provides custom radiator solutions, allowing car enthusiasts and professionals to get radiators that are perfectly tailored to their specific needs. This flexibility makes ALLOYWORKS a go-to choice for those looking to upgrade their vehicle’s cooling system with precision and reliability.

Customer Reviews & Performance Ratings

The excellence of ALLOYWORKS radiators is reflected in the positive reviews and high performance ratings from customers around the globe. Enthusiasts and automotive professionals alike praise the brand for the significant improvements in engine cooling and performance after installing ALLOYWORKS radiators.

Customers frequently highlight the durability and efficiency of ALLOYWORKS products, noting that these radiators consistently deliver superior cooling even under challenging conditions. The robust construction and use of quality materials ensure that ALLOYWORKS radiators withstand the rigors of demanding applications without compromising performance.

Furthermore, ALLOYWORKS is recognized for its excellent customer service, providing support and guidance to ensure the right radiator is chosen and properly installed. This commitment to customer satisfaction is evident in the numerous testimonials praising both the product and the service.

Overall, ALLOYWORKS has established itself as a trusted name in the vehicle accessories market, particularly for those seeking reliable and efficient aluminum radiators. Their commitment to quality, innovation, and customer satisfaction makes them a top choice for anyone looking to enhance their automotive cooling system.

New Radiator Installation & Maintenance Tips

Installing a new radiator is a significant step towards improving your vehicle’s cooling efficiency. Proper installation and routine maintenance are key to ensuring the longevity and performance of your radiator. Here are some essential tips to guide you through the process.

Correct Installation Methods

Ensuring a proper installation is crucial for your radiator to function effectively. Here’s a step-by-step guide to installing a new radiator:

-

Preparation: Before starting, gather all necessary tools and safety equipment. Ensure the engine is cool and disconnect the battery to prevent any electrical hazards.

-

Drain the Coolant: Place a drain pan under the radiator, open the drain valve, and allow the old coolant to empty completely. Properly dispose of the old coolant in accordance with local regulations.

-

Remove the Old Radiator: Disconnect the hoses and any attached components such as the fan shroud or transmission cooler lines. Carefully remove the old radiator, taking note of the positioning for the new installation.

-

Install the New Radiator: Position the new radiator in place, ensuring it fits correctly and securely. Reattach the hoses and any components removed during the disassembly. Ensure all connections are tight to prevent leaks.

-

Refill the Coolant: Once the new radiator is in place, refill the system with the appropriate type and amount of coolant. Bleed the system to remove any air pockets, which can cause overheating.

-

Test the Installation: Start the engine and allow it to reach operating temperature. Check for leaks and ensure the radiator and cooling system function properly.

By following these steps, you can ensure your new radiator is installed correctly, maximizing its efficiency and performance.

Longevity Through Routine Maintenance

Routine maintenance plays a vital role in extending the life of your radiator and ensuring it continues to perform efficiently. Here are some maintenance tips to keep your radiator in top condition:

-

Regular Coolant Checks: Periodically check the coolant level and quality. Low coolant levels can lead to overheating, while contaminated coolant can cause corrosion and damage.

-

Inspect for Leaks: Regularly inspect the radiator and hoses for any signs of leaks. Catching leaks early can prevent more severe issues and costly repairs down the line.

-

Clean the Radiator: Ensure the radiator’s fins are clean and free from debris. Use a soft brush or compressed air to clear any dirt or leaves that may obstruct airflow and reduce cooling efficiency.

-

Monitor Engine Temperature: Keep an eye on the engine temperature gauge. An unexpected rise in temperature could indicate a radiator problem that needs immediate attention.

-

Flush the Cooling System: Perform a coolant flush at least once a year or as recommended by your vehicle’s manufacturer. This helps remove any buildup of minerals or contaminants that can reduce the efficiency of your cooling system.

By adhering to these maintenance practices, you can significantly enhance the longevity and performance of your radiator, ensuring your vehicle remains cool and efficient for years to come.